Third Year Chemical Engineering Laboratory

Froth Flotation Tanks - Chemical Engineering UG Level 3 Labs

![]()

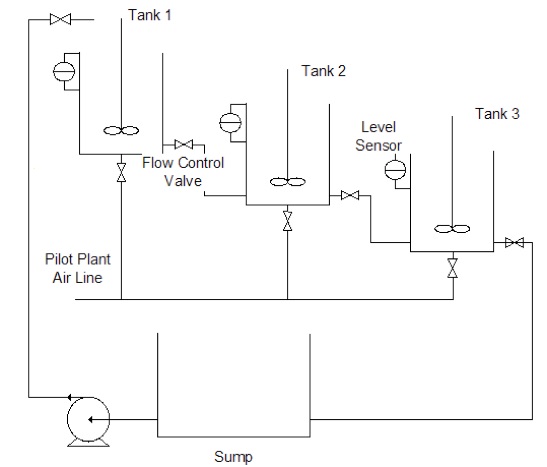

A three-tank floatation system, located in the Pilot Hall, has been built to study the dynamics of a froth flotation process to separate minerals. A schematic of the system is given below. Each tank has a variable speed impeller and can be sparged with air at flow rates of up to 1000ltrs per minute. The outflow from each tank is driven purely by gravity and is controlled by a pneumatic valve. In addition, the height of each of the tanks can be individually adjusted by hydraulic lifts.

![]()

Objectives

1) Assess the COSHH and RISK Assessments for the process.

2) Develop a simple model that describes the levels of the three tanks in order to control and optimise the froth flotation separation process.

3) Optimise the process in terms of yield and energy expenditure to maximise the separation and thus quality and amount of product generated, whilst minimising reagents, resources.

4) Validate the models by the use of appropriately designed experiments.

5) Initially, only water should be used, however include within the model options for utilising surfactant to improve the process and separation.

6) If time is available, conduct additional experiments to validate the use of surfactants in the process.