Biodiesel Production – Engineering a Greener Future

2012 - 13

Biodiesel Production – Engineering a Greener Future

Enhancing the UG/PGT Student Experience & Proposals for Teaching Equipment

Dr Richard Holmes, Dr Nasir Al-Lagtah, Mr Tom Szpitter, Mrs Patricia Turnbull, and Dr Arthur Garforth

School of Chemical Engineering and Analytical Science.

-----

Shortlisted for the IChemE - Education and Training Awards 2013

Sponsored By Costain

Click Here

--------

Synopsis - This proposal aims to address a number of issues simultaneously, offering additional resources for undergraduate chemical engineers in developing and utilising renewable energy resources, whilst also addressing the green policies of the University and contributing to a reduction in the carbon footprint of the university as a whole.

Introduction - The development and utilisation of renewable energy sources presents an array of interesting challenges to chemical engineers and it is important to train future generations of chemical engineers to recognise and address these problems at an early stage in their training and career. This requires a multi-faceted approach, uniting chemical engineers skilled in production and process engineering, sustainability, life-cycle analysis, catalytic development, measurement and analysis, and utility management (combined heat and power systems) to maximise the benefits obtained from a switch from fossil fuels to renewable energy systems. One of the more interesting and useful areas is the development of Biodiesel processing, as the process is relatively straightforward and the process accepts feedstock from a wide range of sources, from alge and nuts to waste vegetable oils, and animal fats.

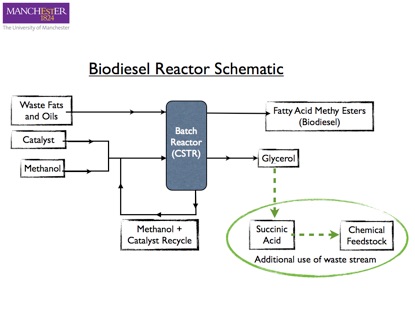

These oils and fats are converted into biodiesel by a process known as trans-esterification, using methanol and sodium hydroxide. The products of the reaction are fatty acid methyl esters (FAMEs) of various lengths depending on the feedstock and glycerol. Additional methods to increase the sustainability of biodiesel includes the use of non-food crops and non-food components of food crops, especially lignocellulose based materials which can be converted using advanced engineering processes into suitable feedstocks. Finally, recent work in the school of Chemical Engineering and Analytical Science has shown that the glycerol from the biodiesel production process can be recycled and converted into succinic acid, which in turn forms a feedstock for commodity chemical production.

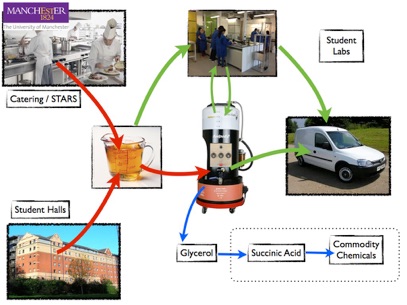

Proposal - As stated previously, the proposal addresses the issue of Biodiesel across the entire curriculum. Starting in first year laboratories, bringing together the chemical sciences and engineering in the form of practical work to generate and analyse biodiesel, and progressing through second, third and fourth year labs and lecture courses. The work would support the theme of renewable energies, which links into a range of academic courses, from Biotechnology and Environmental Technology (UGT2) to Catalytic Reaction Engineering (UGT3) and Sustainable Developments and Industry (UG3) and finally to Sustainability, Resources and Waste (PGT) and Bio-refinery Engineering (PGT). The reinforcement of fundamental knowledge and the chance to apply these tools in a laboratory setting provide an exceptional advantage to student retention, allowing a comprehensive study of real-world issues from a range of angles.

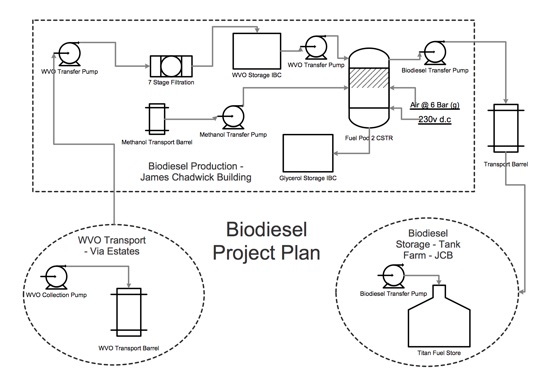

In addition to integrating this topic into UGT and PGT lab and lecture classes, with ever increasing degrees of complexity, from simple small scale batch production to testing, and plant design for large scale bath and continuous processing, there is also the opportunity to address the issue of waste oils within the university, generated by catering services across campus. The concurrent development of a small scale working pilot plant to accept oil feeds from university outlets and convert this into a source of fuel suitable for vehicular and heating / power (CHP) usage would not only demonstrate to undergraduate students the chemical engineering processes on the bench, but also the concepts concerning scaling of processes.

A basic process flow diagram is included below to illustrate the components which form the system.

This proposal has been funded by the University of Manchester - EPS Strategic Fund (2012)