Microfluidic Multiphase Droplets

2008 - 09

Delivery of stabilisation system for microdroplet generation and control

1.Use of Syringe Pumps to replace gravity driven flow.

2.Assessment of carrier phase suitability to generate droplets of compounds of interest

3.Design and Fabrication of Micro-fluidic Channels

4.LabView Controlled Syringe Pumps

5.Basic Crystallisation Experiment

6.Integration of an Ocean Optics Spectrometer

1. Use of syringe pumps to replace gravity driven flow.

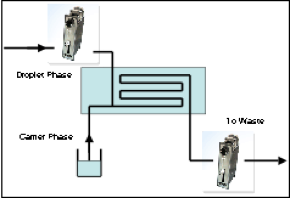

A gravity feed systems is capable of providing flow through complex micro-fluidic channels, however there is significant difficulty in obtaining the optimal arrangement of carrier and droplets phase reservoirs to maintain adequate flow rates. Additionally, it is exceptionally difficult to vary the flow rates of such a system, meaning that dynamic changes in flow rate / droplet generation are non-trivial endeavours.

The use of syringe pumps was designed to offer a greater degree of control over the actual flow rates of droplets produced and allow for dynamic control over the rates during experimental procedures. This introduced a number of issues, mostly around interconnection and back-pressure, since the more complex a micro-channel (moving from straight to serpentine and finally to spiral) gave rise to an increase in back-pressure inside the system. This essentially resulted in a compression of the carrier fluid, which finally resulted in a failure of the device at the weakest junction.

Typically, this weakest junction was the entry connector for the carrier phase, designed to be a push-fit system – resulting in a trivial but time consuming task to relocate the connectors and re-prime the pumping system. Using a stronger connector system at this junction resulted in a more substantial failure of the device, with seals cracking under the extreme back-pressure – usually damaging the device beyond repair.

Whilst the failure of the interconnect was problematic, it did not cause serious problems with the micro-device, however the time-consuming nature of pre-priming the system meant that this was not an acceptable occurrence with the use of the syringe-pump driven system.

As such, an alternative approach was developed, to limit the effects of back-pressure on the system.

This entailed using a fixed height reservoir for the carrier phase positioned at the anterior of the channel system, and the syringe-pump working to draw the carrier phase through the channel, rather than driving it through the channel. Since the carrier phase accounts for the larger volume of fluid in the channel, the back-pressure build-up from using anterior syringes for droplet generation was negligible.

2. Assessment of carrier phase suitability to generate droplets of compounds of interest

The droplet phase of interest was a reverse phase component when compared to the standard water in oil droplet systems utilised in CEAS during previous projects.

The system required a non-aqueous carrier phase, with organic and aqueous phase droplets systems.

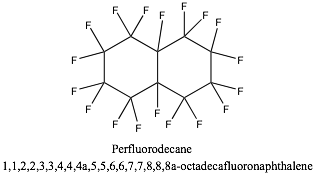

As such this added significantly to the complexity of the project, however a suitable carrier phase system was found using a perfluoronated hydrocarbon – perfluorodecalin (PFD).

It was demonstrated that a significant number of both organic and aqueous solvents formed stable droplets or slugs in PFD, along with the formulation solvent EC-A15149W, which provided results above and beyond expectations. The timing of the syringe pumps occasionally meant that slugs of droplet reagent rather than discrete droplets were produced – however since the flow rates can be modified in a dynamic responsive mode, this was not felt to be a significant problem.

Ethanol in Perfluorodecalin - Droplets formed and stabilized

2-propanol in Perfluorodecalin - Droplets formed and stabilised

Toluene in Perfluorodecalin - Droplets formed and stabilised

Tetrahydrofuran in Perfluorodecalin - Discrete slugs formed and stabilised - Droplet formation should be trivial

Acetone in Perfluorodecalin - Discrete slugs formed and stabilised - Droplet formation should be trivial

1-Octanol in Perfluorodecalin - Discrete slugs and droplets formed and stabilised.

Hexane in Perfluorodecalin - Partitioning of two solvents, no droplet formation

2,2,4-trimethyl pentane in perfluorodecalin - Partitioning of two solvents, no droplet formation

EC-A15149W in perluorodecalin - Discrete slugs formed and stabilised - Droplet formation should be trivial.

3. Design and Fabrication of Micro-fluidic Channels

Compatibility of the typical device materials with the carrier and droplet phases proved problematic, as direct machining of PMMA provided channels of the required dimensions, but which were not compatible with the solvent mixtures.

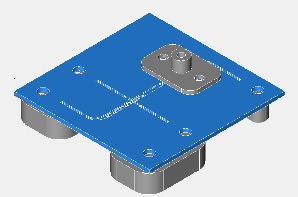

Numerous materials approaches were attempted, including coating of surfaces to change the surface properties, however the eventual system was developed using a micro-machined base place, and a length of PTFE tubing. Whilst direct machining of PTFE is possible, bonding and sealing of such a device is not currently possible.

The use of Telfon coatings was also investigated, however the technique proved more troublesome than initially envisaged and the use of the PTFE tubing system was adopted to expedite results.

Additionally, a novel bonding technique was developed using polyaniline and a domestic microwave. However, this system was only suitable for PMMA devices.

4. LabView Controlled Syringe Pumps

A control software system developed by BJTB and RJH was used to control the syringe pumps system. This was developed as part of a number of previous projects by BJTB, with RJH defining changes to accommodate the functions required.

A four-syringe pump instrument had been constructed for a previous project, and this was re-tasked for use with this project.

5. Basic Crystallisation Experiment

A desired experimental system was the development of a method to monitor crystallisation within the micro-droplet. Benzoic acid in methanol was used as a template system, due to its well-characterised nature.

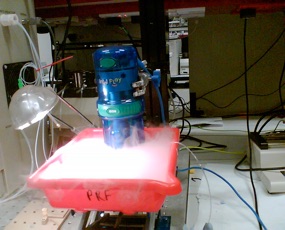

An ice bath was used to cool the system and promote crystallisation however difficulties in imaging prevented any viable results form being obtained. It was also thought that the thermal conductivity of PFD might be affecting the ability of the benzoic acid droplets to crystallise, the other consideration was the lack of nucleation sites inside a perfectly spherical droplet.

Dry ice was used to rapidly cool the system, with the intention that the visualisation of any crystallisation would be a significant step forward. Unfortunately this simply froze the carrier phase, invalidating the results.

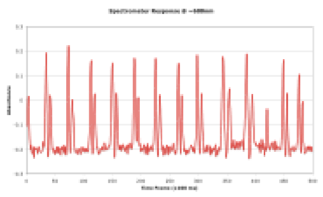

6. Integration of an Ocean Optics Spectrometer

Detection in the microsystem was an important consideration, and given the availability of the Ocean Optics Spectrometer, it was decided to use this as a method of quantification.

A mounting system was developed to locate the fibres in close proximity to the flow system, and dyed droplets were passed through the channel, with the spectrometer detecting the droplet transition.

Initial trials were only able to detect the leading and training faces of the droplets, rather than perform spectroscopy on each droplet, however the results were promising.

Further Results

Perfluorodecalin Carrier Phase

Oil Red Dye + solvents

Syringe Pump System + Manual injection

Toluene 2,2,4-Trimethyl Pentane

1-Octanol Hexane